We are delighted to announce that the WAHA is a supporting association sponsor of the Workplace Health & Safety Show!

Packed full of exhibits, live demos, seminars, workshops, networking – and attended by thousands of health and safety professionals – this all-encompassing event provides the knowledge, tools, resources and connections you need to achieve world-class safety.

Register FREE for the Workplace Health & Safety Show in Melbourne (22-23 May 2024, at the Melbourne Convention & Exhibition Centre) to get up-to-date insights, including tips for working at heights, safely!

Adaptive Learning and Working At Heights

Over the course of the last 8 months, one of the primary projects of the Association has been a partnership with WAHA Gold Member, Area9 Lyceum: a global leader in AI Adaptive learning. Supporting this collaboration is John Holland and Programmed, industry leaders in their respective sectors but with a shared vision to reduce risk and improve safety in regards to falls prevention. This collaboration between organisations has led to the development of an adaptive learning working at heights course; which is now in the final stages of pilot testing. Before we elaborate more on this project, it’s best to understand how we got there.

Current Challenges

This project came about through the identifiable gaps in the levels of competency delivered under the current RTO framework for safe Working at Height. We know without a doubt that the model is flawed and often leaves critical gaps in skills and knowledge which in turn increases the potential for safety incidents.

Skills shortage

These issues are compounded by labour shortages across multiple sectors which leads to engagement of work forces with lower levels of knowledge, skills and experience. Whilst compliance training is being undertaken, there is no guarantee genuine competency is being delivered, and it is these ‘unknown unknowns’ from each worker which is of the greatest concern.

Organizations simply do not have line of sight on the ‘transparency of competency’ and have to assume training is relevant and workers safe to work at height.

Shared Vision

Through collaboration with likeminded parties, like Area9 Lyceum, we are supporting the empowerment of operators at height in multiple industries to work more safely by providing relevant, intuitive, and practical education via an AI learning model. The a solution that provides not only validation of competencies across this workforce but eliminate the gaps in knowledge critical to safe work practices. The vision is for this course to be used across multiple industries, allowing learners to build competencies, reduce risk as they move from site to site. A Falls Protection White Card!

The Courses

The combined focus of our partners will deliver a modular training package with targeted key learning areas and the flexibility to be tailored to suit roles, worksites and offer each learner a personalised learning experience. This will serve to reduce risk, save time, improve safety outcomes, and provide high levels of actionable data.

Key goals of the collaboration include:

- Saving lives in the workplace.

- Meaningful and cost-effective interventions that can be tailored and scaled to maximize impact.

- Build stronger skills and competency across multiple sectors with regards to falls prevention.

- Reduce risk and improve safety outcomes.

- Impact and influence behaviour change at the operational level.

These project outcomes align with WAHA strategic plan through:

- External stakeholder engagement.

- WAHA as a positive influence for change.

- Education and empowerment of all stakeholders.

Tailored to specific work settings

The ability to create versions specific to facility management, utilities and construction with heightened efficiencies and effectiveness, the focus will be on the engagement of partners to utilise the courses across induction and training activities.

While training staff and subcontractors, the modules can be delivered both directly to employees through existing LMS infrastructure, through subcontractor portals such as Donesafe and 3D Safety or contractors can access directly through Area9 Lyceum’s portal, Rhapsode.

So, what exactly is Adaptive Learning?

It is an online delivery method that automatically adjusts to the needs of each learner. It recreates at scale the optimal teaching approach of a one-on-one personal tutor. It uses proven data analytics and intelligent technologies to adjust in real-time to deliver an optimal experience.

Gaps in knowledge have significant impact when working in high-risk environments with significant exposures to falls. Where standard eLearning is a ‘one size fits all’ solution and does not address in competency, adaptive AI learning provides a personal teaching experience for each learner but at scale. With over 30 million users, evidence shows gaps in knowledge are eliminated, and there is up to 50% time saving in the delivery when compared against standard eLearning, leading to improved safety and reduced risk in a range of settings including construction, mining, and utilities.

Current eLearning, as good as it may look, simply does not support individuals. It leaves considerable gaps, and creates risk exposure and potentially false confidence, especially in high-risk industries. If we were to take a cynical position, a lot of what is being delivered could be considered an exercise in compliance rather than building a genuinely competent workforce.

The AI within Area9 Lyceum solution evaluates each learner using over 1 billion data points as they work through your existing or new training content and supports the individual’s gaps in knowledge. This has significant impact on the development of competencies and has a personalized learning approach at scale.

The key aspects for the success of this adaptive learning in high-risk environments such as utilities / construction/ mining / transport and medicine are:

- A proven method of learning with over 30 million users.

- Elimination of critical knowledge gaps for each learner that standard eLearning fails (compliance driven only), but at scale (personal tutor).

- Supports behavioural change and enhances operational and field training.

- Saves up to 50% in time due to the personalised approach when compared to standard eLearn course (proven to increase productivity and reduce costs).

- High engagement of staff due to the personalised approach.

- Provides exquisite data to support the impact of the educational intervention and reduction in risk.

- Works in all LMS.

- Project outcomes align with WAHA strategic plan.

- External stakeholder engagement.

- WAHA as a positive influence for change.

- Education and empowerment of all stakeholders.

The WAHA and Area9 are proud to partner with Programmed and John Holland Group in the development of our first packages targeting verifiable competency in the construction and facility management sectors. With their support we have developed content building on the core competencies as determined by the RTO framework and contextualized via a scenario-based module focused specifically on work practices, environments and practical application of their knowledge for those worksites. Connecting with the workforce and providing relevant contexts for this knowledge has been shown to have a significant impact on safety practices and statistics.

This program is the first of its kind, and WAHA are very excited to be at the forefront of using this technology to affect change on a large scale.

Based on the project structure, content, and approach, WAHA and Area9 are also in negotiations with other industry sectors and large organisations to implement the program as standard industry requirements for safety.

There are developments already in the planning stages, for not only other industry specific scenario content (written in collaboration with SMEs in those sectors), but also expanding the content to include working at heights supervisor, systems installer, systems design, inspection, and technology programs to be delivered to continue to increase the knowledge and professionalism of our industry and to support our members.

2024 will be a big year for WAHA, and on the back of the success of this project, we will be in the best position in the history of the Association to deliver great outcomes for safety, our allies and advocates, and our members.

Standards Australia release Work at Height small-business set subscription.

Standards Australia release a curated Subscription Service for Small Businesses: What you need to know about the Work at Height Set.

Nearing on three years ago, WAHA members enquired about the possibility of receiving discounted access to Standards through our involvement with the SF015 Committee. Whilst exploring this opportunity, the Standards Australia store was going through a complete overhaul, in preparation for launching subscription access to Standards.

As part of Standards Australia’s shop development, the idea of a small curated suite of Standards was raised: making a bundle available to subscribers, instead of purchasing outright, users would be able to gain access to more, for less over time, and receive access to any updated standards that are part of the set, at no extra cost.

After a few months of working together, Standards Australia and the Working at Height Association came refine a list of Standards and we are pleased to announce that there is a “Work at Height” set available, curated for small businesses.

Working at heights refers to any job where individuals may face the risk of falling from one level to another. The standards in this set have been developed to provide guidelines and best practices for preventing falls and protecting workers across various industries including construction, civil engineering, confined spaces, residential and more.

This set is suitable for a wide range of professionals who work in environments where there is a risk of falling from one level to another. This includes site safety supervisors, rope access workers, height safety specialists, facilities management personnel, fall prevention system installers or re-certifiers, inspectors of height safety systems, engineers, architects, and designers.

It could also be relevant for manufacturers of fall prevention equipment and personal protective equipment.

The standards in this set help to ensure safety and compliance in preventing falls and injuries, with the aim of reducing the risk of significant harm to workers.

The Work at Height Set also offers subscribers:

- Access to the most-used standards in the industry

- Digital standards access across multiple devices

- A 2-user licence within their organisation

- The peace of mind that comes with automatic updates to all standards within the set

- Annual subscription terms at an affordable price

HOW DOES THIS SET HELP THE USER DO THEIR JOB?

The standards in this set provide clear guidelines and best practices for working at heights, helping to reduce the risk of falls and injuries. Typical tasks these standards can help provide guidance on include climbing a ladder, accessing or exiting a work area, working near an excavation or void, working on a roof or exposed surface, working near an edge, work in fall-arrest or work positioning, and more.

As well as helping ensure safety and compliance, access to these standards:

• Provides in-depth industry knowledge to improve efficiency

• Affirms a business as a reputable operator

• Supports consistency across projects

WHAT’S INCLUDED IN THIS SET?

The standards in this set are referenced in the WHS Act as well as several state and territory regulations, making them a crucial resource for employers and workers to fulfil legal obligations and maintain a safe work environment.

This set includes:

- AS/NZS 1891.4:2009, Industrial fall-arrest systems and devices, Part 4: Selection, use and maintenance

- AS/NZS ISO 22846.2:2020, Personal equipment for protection against falls — Rope access systems, Part 2: Code of practice

- AS 1892.5:2020, Portable ladders, Part 5: Selection, safe use and care

- AS 1657:2018, Fixed platforms, walkways, stairways and ladders — Design, construction and installation

- AS/NZS ISO 22846.1:2020, Personal equipment for protection against falls — Rope access systems, Part 1: Fundamental principles for a system of work

- AS 2865-2009, Confined spaces

Subscribe to the Work at Height Set from the Standards Australia Store today.

Conviction after fall leaves worker with spinal injuries

Source: WorkSafe Victoria.

A metal fabrication subcontractor has been convicted and fined $35,000 after a worker was seriously injured when he fell four metres at Tullamarine.

Karagata Australia Pty Ltd was sentenced in the Melbourne Magistrates’ Court on Friday after pleading guilty to a single charge of failing, so far as reasonably practicable, to maintain a safe working environment.

The company was also ordered to pay costs of $5,000.

The court heard that two workers and the company director were installing a mesh walkway on a mezzanine level at Melbourne Airport in December 2021, working from an aluminium plank that was resting on – but not fixed to – metal beams.

When the plank overturned, one of the workers fell through a ceiling panel onto the floor four metres below. He was taken to hospital suffering multiple injuries, including fractures and spinal injuries.

A WorkSafe investigation found that Karagata Australia had failed to eliminate or control the risk of a fall by using a fall arrest system, such as a crash deck.

The court heard it was also reasonably practicable for the company to have had a Safe Work Method Statement that sufficiently described measures to control the risk of falling and how they would be implemented, and to ensure high risk construction work was carried out in accordance with the statement.

WorkSafe Executive Director Health and Safety Narelle Beer said there was no excuse for not putting safety first when working at heights.

“It takes just seconds for a worker to fall and the consequences can be devastating, including shocking injuries and loss of life,” Dr Beer said.

“More than 160 workers have already been seriously injured falling from heights this year, yet despite the well-known risks, we still see people working at heights without appropriate protection, often with terrible consequences.”

To prevent falls from height employers should:

- Eliminate the risk by, where practicable, doing all or some of the work on the ground or from a solid construction.

- Use a passive fall prevention device such as scaffolds, perimeter screens, guardrails, safety mesh or elevating work platforms.

- Use a positioning system, such as a travel-restraint system, to ensure employees work within a safe area.

- Use a fall arrest system, such as a harness, catch platform or safety nets, to limit the risk of injuries in the event of a fall.

- Use a fixed or portable ladder, or implement administrative controls.

Don’t overlook height safety equipment inspections

Article by WAHA Gold Member; RIGCOM.

When considering height safety systems installed to protect workers at height, the focus is often on their design, installation and use. However, an important step and your legal obligation as the owner and or provider of these assets are often overlooked, that is the management of their: Maintenance, Inspection, and Re-certification.

Don’t overlook height safety equipment inspections. Failing to implement a proper inspection regime poses significant risks to both the operator and the employer, as well as potential damage to plant and equipment.

The importance of height safety equipment inspection

Over time, frequent use, wear and tear and exposure to industrial environments can cause height safety and fall protection equipment and systems to deteriorate. In some instances, it can lead to failure. The significance of conducting regular equipment inspections cannot be overstated; it is of utmost importance. Regardless of industry and experience, the dangers of working at height are real, and the consequences of an incident are devastating. Let’s face it, accidents happen, and the last thing you need is for your equipment to fail when you need it most.

The maintenance, inspection and re-certification of your height safety equipment and systems is vital, which is why it is not only required under Australian and New Zealand Standards but also mandated by law in certain states. It is essential that competently trained and accredited individuals perform thorough testing, inspections and tagging to ensure equipment safety and compliance.

Your obligations under the standard

AS/NZS 1891.4 specifies requirements and sets out recommendations for the selection, safe use and maintenance of industrial fall-arrest systems and devices based on the use of safety harnesses, horizontal lifelines and rails, fall-arrest devices, and associated lanyards, connectors, anchorages and fittings. The standard outlines the recommendations for inspection to ensure that the items are in good working order and ensure the health and safety of workers exposed to a risk of injury from a fall.

The Standard requires that height safety equipment be:

- Inspected by a ‘Competent Person’ before and after use

- Inspected by a ‘Height Safety Equipment Inspector’ every six or twelve months (dependant on equipment type)

The Standard also stipulates that records of inspection and maintenance must be recorded in an inspection and maintenance log maintained by the company, and made available to operators, users of the equipment and regulators as required.

Dropped Objects

Falls from height continue to be a major cause of serious accidents in the workplace. Notwithstanding the overall improvement of health and safety at work over recent years, falls from height still occur. Indeed, falls from height were one of the principal cause of fatalities in the 2022 period, comprising 9% of all fatalities according to Safe Work Australia figures.

What makes 2022 a particularly disturbing year, was that 9% of fatalities also occurred from dropped or falling objects.

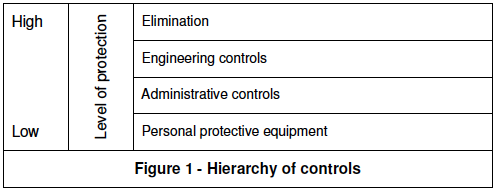

We spend a significant amount of time studying and implementing control measures to keep workers safe; the risk presented by dropped objects can be managed by adopting an hierarchical approach (see Figure 1), with the level of protection reducing as the lower levels are reached.

This should a familiar hierarchy, as the framework set out by the ‘hierarchy of fall protection’: Avoid, Prevent, Mitigate.

i.e. minimise the distance and consequences of a falling or dropped object.

Some measures are ‘collective’ (and ‘passive’), e.g. safety nets. Others are ‘personal’ (and ‘active’), e.g. tool lanyards. It is important to select suitable equipment, taking account of the mass of the object being retained and the situation in which it is to be used.

There are two types of falling or dropped object:

(a) Static: An object that may drop from its previous static position under its own mass, e.g. a light fitting that drops due to its fasteners coming loose over time.

(b) Dynamic: An object that drops from its previous static position due to the force applied by a person, wind, equipment, machinery or moving object, e.g. an object being knocked off a platform and dropping to a level below.

ELIMINATION

Where possible, the elimination of a hazard – or avoidance – must be the preferred option. There are many steps you can take at the beginning of your work day, and throughout, to ensure your workplace remains safe. Undertaking pre-job checks, or surveys to look for potential problems, taking the time to maintain a clean and tidy worksite. This is hugely important when returning to a site after bad weather, or on new sites, and after third party operations in the same area.

You can ensure that pockets are empty, take the time to inspect tools before starting work, checking for lanyard fixings, quality of lanyards or loose components. Consider what precautions you can take for ‘high energy’ hand tools.

Don’t take or carry too many tools or items, or consider how they can be secured and transported safely for use on site.

ENGINEERING CONTROLS

If the hazard cannot be eliminated, engineering controls are the preferred approach to risk reduction. This involved the use of equipment to reduce the potential for dropped objects (or, preferably, prevent them from being dropped), or to reduce the risk if an object does fall.

Examples include:

• temporary covers being placed around and/or over openings;

• work clothing has pockets these should be capable of being securely closed; preferably, don’t put loose items in pockets;

• tools being transported in securely closed containers, e.g. when being lifted between levels;

• lightweight hand tools, communication equipment, etc. being tethered to the technician;

• replacing a hand held torch with a helmet mounted head torch;

• heavier tools and components being separately tethered;

• using safety netting to catch tools or equipment that cannot be tethered, e.g. bolts;

• providing ‘hard’ barriers, toe boards, etc. to form an exclusion zone, where it is not possible to prevent dropped objects.

ADMINISTRATIVE CONTROLS

Administrative controls, to be used in conjunction with other controls in the hierarchy, involve providing:

• information and warnings to technicians about hazards that are present;

• procedures and instruction on how to carry out the work safely;

• supervision to ensure that any procedures are being followed;

• management processes to determine any ‘lessons learnt’.

Examples of administrative controls include:

• hazard awareness, e.g. at induction;

• warning signs, to highlight any hazards to the workers;

• planning activities to avoid situations where work is being carried out at multiple levels simultaneously;

• lookouts to prevent people entering an area below where technicians are working;

• high levels of workplace housekeeping, i.e. keeping works areas clear of loose material or objects;

• operating systems to check that all tools and components have been removed from, or secured in, the work area prior to completion of the task;

• processes for reporting, investigating and learning from hazardous observations and incidents involving falling objects (and developing a culture in which reporting is encouraged).

PERSONAL PROTECTIVE EQUIPMENT

This is the last method of protecting an employee.

Industrial safety helmets provide limited protection only, due to the high level of kinetic energy that falling and dropped objects possess. A helmet protects the head only, so other areas of the body are unprotected from dropped objects and serious injuries can easily be suffered, e.g. face.

For more information:

IRATA International Topic Sheet No. 11

Safe Work Australia Key Work Health and Safety Statistics, 2023

NSW Government to transform SafeWork NSW into standalone work, health and safety regulator.

Source: SafeWork NSW

The New South Wales Government will transform SafeWork into a standalone regulator following a 12-month inquiry by former judge The Hon. Robert McDougall KC.

The Government has released the independent report as it continues work to create a modern, strong and fit for purpose work health and safety regulator.

The Government has endorsed the report’s recommendations with further work underway to determine specific implementation details.

Many of the recommended reforms started after March last year, including reviewing SafeWork’s capabilities in triaging of incidents, improving the responsiveness of contact centre staff and pulling together SafeWork staff previously spread across the Department of Customer Service.

Other critical recommendations include:

- Requiring SafeWork to keep those affected by workplace incidents, including families of deceased workers and those seriously injured at work, informed of progress of investigations and prosecutions,

- Training more inspectors in dealing with psychosocial hazards in the workplace such as extreme workload and bullying,

- Reviewing complaints handling policies,

- Formalising data collection and analysis to make better compliance and enforcement decisions.

In opposition, Labor fought for the establishment of this inquiry to ensure that workers were protected, following a spate of scandals under Liberal-National Ministers such as an inadequate response to the emerging silica threat.

The Independent Review was informed by public consultation including submissions by former and current SafeWork staff, families of injured and deceased workers, unions and peak bodies, employer groups and SafeWork itself.

Detailed options are being developed on the possible design of the standalone regulator for the Government’s consideration.

Minister for Work Health and Safety Sophie Cotsis said:

“This Government commits to all NSW workers that it will never allow the health and safety regulator to be compromised so badly again.”

“Worker safety is not red tape, it is not a tick a box function, it is not a cost of doing business.”

“It is a fundamental right for every worker to go to their job and come home safely.”

“We are committing to ensuring for family members that SafeWork will create improved processes to ensure they are informed at all steps of an investigation.

“We are committing to SafeWork’s inspectors that they will get the support they need to do their vital work.”

“I thank the Hon. Robert McDougall KC and those who made submissions to the review for their work.”

SafeWork NSW’s Trent Curtin said:

“SafeWork NSW is entering a new era. Our dedicated and passionate staff want to make sure that everyone that goes to work can come home safely.”

“The recommendations set out by the Hon. Robert McDougall KC will assist SafeWork to become a strong and responsive work health and safety regulator for NSW.”

“With work already underway, SafeWork NSW will take all steps necessary to analyse our regulatory approaches and support systems to ensure best-practise work health and safety regulation for NSW workers.”

Prevention focus on deaths and injuries from construction falls

Source: WorkSafe Victoria.

Hundreds of construction workers suffered workplace harm last year after falling from height on the job.

This week WorkSafe will launch a statewide blitz to tackle fall risks such as unsafe or incomplete scaffolds, inappropriate ladder use, steps, stairs and voids or falling from or through roofs on building sites across Victoria.

Tragically, nine Victorian workers died in 2023 as a result of a fall from height, including four in the construction industry. The number of accepted claims from construction workers injured in falls from heights increased to 441 – up from 421 in 2022 and 404 the year before.

WorkSafe Executive Director Health and Safety Narelle Beer said inspectors would be out in force with an extra emphasis on ensuring employers are doing everything they can to prevent falls.

“As a leading cause of injury in the construction industry, falls from height is always a priority for our inspectors – but they will be making this a particular focus as they visit building sites over the coming weeks,” Dr Beer said.

“The safest way to prevent falls is to work on the ground. Where that’s not possible, employers should use the highest level of safety protection possible, such as complete scaffolding, guard railing and void covers.”

Construction continues to be the highest-risk industry for falls from heights, making up a third of the 1,352 total falls from height claims accepted last year.

Of the construction workers injured, 160 fell from ladders, 46 from steps and stairways, 31 from buildings or structures, 27 from scaffolding, and 13 from openings in floors, walls or ceilings.

Dr Beer said WorkSafe can and will take action against employers who fail to ensure the highest level of risk control measures are in place to protect workers from falls.

“A fall can happen in just seconds and it can turn your world upside down – so there’s no excuse for taking shortcuts when working at heights.”

The statewide blitz will be supported by falls prevention messaging across social media, newsletters and online, reminding employers and workers that falls can be fatal or cause life changing injuries.

To prevent falls from height employers should implement the highest possible measures from the five levels in the hierarchy of controls:

- Level 1 Eliminate the risk by, where practicable, doing all or some of the work on the ground or from a solid construction.

- Level 2 Use a passive fall prevention device such as scaffolds, perimeter screens, guardrails, safety mesh or elevating work platforms.

- Level 3 Use a positioning system, such as a travel-restraint system, to ensure employees work within a safe area.

- Level 4 Use a fall arrest system, such as a harness, catch platform or safety nets, to limit the risk of injuries in the event of a fall.

- Level 5 Use a fixed or portable ladder, or implement administrative controls.

For more information visit worksafe.vic.gov.au/fall-prevention

Charges laid after fatal fall through shed roof

A Monbulk nursery and horticulture supply company has been charged after a worker suffered fatal head injuries when he fell 3.5 metres through a shed roof onto a concrete floor. The 66-year-old maintenance worker fell through polycarbonate roof sheeting, which he was in the process of replacing, in June 2022. Van Berkel Distributors Pty Ltd is facing three charges under section 21(1) of the Occupational Health and Safety Act for failing, as far as reasonably practicable, to provide and maintain a safe working environment.

The company also allegedly breached regulation 327(1) of the Occupational Health and Safety Regulations by performing high risk construction work without a safe work method statement (SWMS). It is alleged that the company also breached section 21(2)(a) of the OHS Act by failing to provide and maintain a safe system of work; and regulation 44(4) of the OHS Regulations by failing to use a fall arrest system.

The matter will be addressed at a filing hearing on 28 February 2024.

Safe Work Australia release digital SWMS tool.

Source: Safe Work Australia

Complacency kills. When hazardous work is undertaken without a clear plan for how to do it safely, workers can be injured or killed.

Everyone who works in construction needs to know what a SWMS is for and how to use it. Our new interactive SWMS tool will help you do this.

Review here: Interactive SWMS Guidance Tool

This tool is for:

- people responsible for preparing and using a Safe Work Method Statement (SWMS) for high risk construction work (HRCW)

- a small business that has to prepare their own SWMS

- people new to the construction industry.

This tool will help you understand:

- what a SWMS does, how it makes a difference, and what the model work health and safety (WHS) laws say about preparing and using a SWMS

- how to prepare a SWMS

- how to use a SWMS in the workplace and keep it up to date.

It includes videos and activities to help explain how a SWMS works. You can work through the entire tool, or click on the module you are interested in below to go straight to the information you need.