Over the course of the last 8 months, one of the primary projects of the Association has been a partnership with WAHA Gold Member, Area9 Lyceum: a global leader in AI Adaptive learning. Supporting this collaboration is John Holland and Programmed, industry leaders in their respective sectors but with a shared vision to reduce risk and improve safety in regards to falls prevention. This collaboration between organisations has led to the development of an adaptive learning working at heights course; which is now in the final stages of pilot testing. Before we elaborate more on this project, it’s best to understand how we got there.

Current Challenges

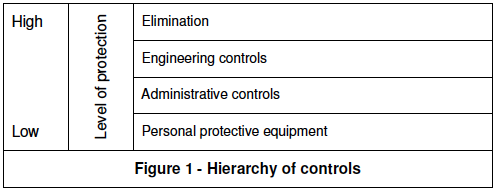

This project came about through the identifiable gaps in the levels of competency delivered under the current RTO framework for safe Working at Height. We know without a doubt that the model is flawed and often leaves critical gaps in skills and knowledge which in turn increases the potential for safety incidents.

Skills shortage

These issues are compounded by labour shortages across multiple sectors which leads to engagement of work forces with lower levels of knowledge, skills and experience. Whilst compliance training is being undertaken, there is no guarantee genuine competency is being delivered, and it is these ‘unknown unknowns’ from each worker which is of the greatest concern.

Organizations simply do not have line of sight on the ‘transparency of competency’ and have to assume training is relevant and workers safe to work at height.

Shared Vision

Through collaboration with likeminded parties, like Area9 Lyceum, we are supporting the empowerment of operators at height in multiple industries to work more safely by providing relevant, intuitive, and practical education via an AI learning model. The a solution that provides not only validation of competencies across this workforce but eliminate the gaps in knowledge critical to safe work practices. The vision is for this course to be used across multiple industries, allowing learners to build competencies, reduce risk as they move from site to site. A Falls Protection White Card!

The Courses

The combined focus of our partners will deliver a modular training package with targeted key learning areas and the flexibility to be tailored to suit roles, worksites and offer each learner a personalised learning experience. This will serve to reduce risk, save time, improve safety outcomes, and provide high levels of actionable data.

Key goals of the collaboration include:

- Saving lives in the workplace.

- Meaningful and cost-effective interventions that can be tailored and scaled to maximize impact.

- Build stronger skills and competency across multiple sectors with regards to falls prevention.

- Reduce risk and improve safety outcomes.

- Impact and influence behaviour change at the operational level.

These project outcomes align with WAHA strategic plan through:

- External stakeholder engagement.

- WAHA as a positive influence for change.

- Education and empowerment of all stakeholders.

Tailored to specific work settings

The ability to create versions specific to facility management, utilities and construction with heightened efficiencies and effectiveness, the focus will be on the engagement of partners to utilise the courses across induction and training activities.

While training staff and subcontractors, the modules can be delivered both directly to employees through existing LMS infrastructure, through subcontractor portals such as Donesafe and 3D Safety or contractors can access directly through Area9 Lyceum’s portal, Rhapsode.

So, what exactly is Adaptive Learning?

It is an online delivery method that automatically adjusts to the needs of each learner. It recreates at scale the optimal teaching approach of a one-on-one personal tutor. It uses proven data analytics and intelligent technologies to adjust in real-time to deliver an optimal experience.

Gaps in knowledge have significant impact when working in high-risk environments with significant exposures to falls. Where standard eLearning is a ‘one size fits all’ solution and does not address in competency, adaptive AI learning provides a personal teaching experience for each learner but at scale. With over 30 million users, evidence shows gaps in knowledge are eliminated, and there is up to 50% time saving in the delivery when compared against standard eLearning, leading to improved safety and reduced risk in a range of settings including construction, mining, and utilities.

Current eLearning, as good as it may look, simply does not support individuals. It leaves considerable gaps, and creates risk exposure and potentially false confidence, especially in high-risk industries. If we were to take a cynical position, a lot of what is being delivered could be considered an exercise in compliance rather than building a genuinely competent workforce.

The AI within Area9 Lyceum solution evaluates each learner using over 1 billion data points as they work through your existing or new training content and supports the individual’s gaps in knowledge. This has significant impact on the development of competencies and has a personalized learning approach at scale.

The key aspects for the success of this adaptive learning in high-risk environments such as utilities / construction/ mining / transport and medicine are:

- A proven method of learning with over 30 million users.

- Elimination of critical knowledge gaps for each learner that standard eLearning fails (compliance driven only), but at scale (personal tutor).

- Supports behavioural change and enhances operational and field training.

- Saves up to 50% in time due to the personalised approach when compared to standard eLearn course (proven to increase productivity and reduce costs).

- High engagement of staff due to the personalised approach.

- Provides exquisite data to support the impact of the educational intervention and reduction in risk.

- Works in all LMS.

- Project outcomes align with WAHA strategic plan.

- External stakeholder engagement.

- WAHA as a positive influence for change.

- Education and empowerment of all stakeholders.

The WAHA and Area9 are proud to partner with Programmed and John Holland Group in the development of our first packages targeting verifiable competency in the construction and facility management sectors. With their support we have developed content building on the core competencies as determined by the RTO framework and contextualized via a scenario-based module focused specifically on work practices, environments and practical application of their knowledge for those worksites. Connecting with the workforce and providing relevant contexts for this knowledge has been shown to have a significant impact on safety practices and statistics.

This program is the first of its kind, and WAHA are very excited to be at the forefront of using this technology to affect change on a large scale.

Based on the project structure, content, and approach, WAHA and Area9 are also in negotiations with other industry sectors and large organisations to implement the program as standard industry requirements for safety.

There are developments already in the planning stages, for not only other industry specific scenario content (written in collaboration with SMEs in those sectors), but also expanding the content to include working at heights supervisor, systems installer, systems design, inspection, and technology programs to be delivered to continue to increase the knowledge and professionalism of our industry and to support our members.

2024 will be a big year for WAHA, and on the back of the success of this project, we will be in the best position in the history of the Association to deliver great outcomes for safety, our allies and advocates, and our members.