How to determine whether a space is a confined space

A confined space is determined by the structure and a specific set of circumstances. The same structure may or may not be a confined space depending on the circumstances when the space is entered. Entry to a confined space is considered to have occurred when a person’s head or upper body enters the space.

A space may become a confined space if work that is to be carried out in the space would generate harmful concentrations of airborne contaminants.

Temporary control measures such as providing temporary ventilation or achieving a satisfactory pre-entry gas test will not cause a confined space to be declassified. For a confined space to be declassified as a non-confined space, it needs to have undergone sufficient changes in structure and use to eliminate all inherent hazards that define a confined space.

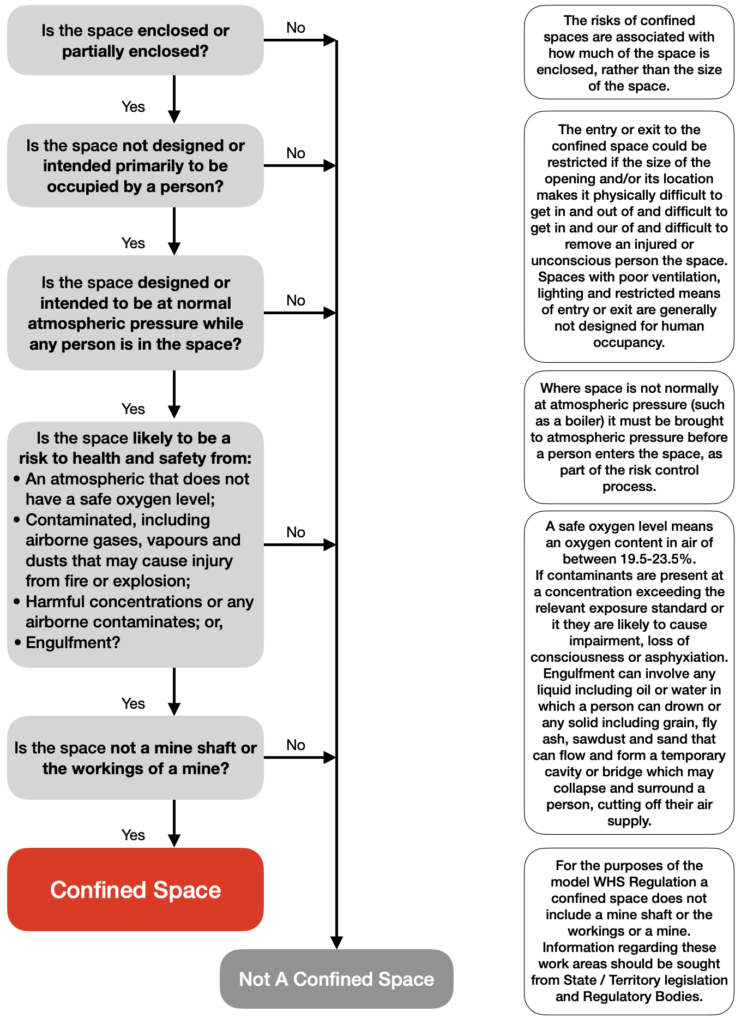

The following flowchart will help to determine whether a space is a ‘confined space’ for the purposes of the WHS Regulations.

Between 2000-2012

59 workers were killed

in confined spaces*

- Selman et al. (2017) Work-related traumatic fatal injuries involving confined spaces in Australia, 2000-2012

What is not a confined space for the purposes of the WHS Regulations?

A confined space does not include a mine shaft or the workings of a mine.

The following kinds of workplaces are also generally not confined spaces for the purposes of the WHS Regulations:

places that are intended for human occupancy and have adequate ventilation, lighting and safe means of entry and exit, such as offices and workshops

some enclosed or partially enclosed spaces that at particular times have harmful airborne contaminants but are designed for a person to occupy, for example abrasive blasting or spray painting booths, and

enclosed or partially enclosed spaces that are designed to be occasionally occupied by a person if the space has a readily and conveniently accessible means of entry and exit via a doorway at ground level, for example:

a cool store accessed by a LPG powered forklift to move stock—although the use of a LPG powered forklift in a cool store can be hazardous, the door at ground level means that once the alarm is raised, escape and rescue can happen quickly; or,

a fumigated shipping container with a large ground level opening that will facilitate escape and rescue.

Trenches are not considered confined spaces based on the risk of structural collapse alone, but will be confined spaces if they potentially contain concentrations of airborne contaminants that may cause impairment, loss of consciousness or asphyxiation.

Who has health and safety duties in relation to confined spaces?

Duty holders who have a role in managing the risks of working in confined spaces include:

- persons conducting a business or undertaking (PCBUs);

- designers, manufacturers, importers, suppliers, installers and constructors of plant, substances or structures; and,

- officers.

Workers and other persons at the workplace also have duties under the WHS Act, such as the duty to take reasonable care for their own health and safety at the workplace.

A person can have more than one duty and more than one person can have the same duty at the same time.

A duty of care is placed on all workers to:

- take reasonable care for their own health and safety;

- take reasonable care that their acts (or omissions) do not harm others;

- comply with reasonable safe work instructions of the PCBU; and,

- comply with reasonable safe work policies and procedures of the PCBU.

The following are key elements of the Model WHS Act and Regulations:

- Early consultation and identification of risks can allow for more options to eliminate or minimise risks and reduce the associated costs.

- Consultation and participation of workers in the design and operation of WHS is required in each workplace

- Specific reporting requirements to the regulator are outlined for incidents defined as notifiable.

- Requirements to implement permit systems for workers engaged in high risk work (i.e. work in a confined space).

“Reasonable practicability” is a concept referred to regularly throughout the Model WHS Act and Regulations and requires that which is reasonably able to be done, at any particularly point in time, to be done to ensure work health and safety.

Reasonable practicability requires consideration of identified hazards / risks and potential control measures available to eliminate or minimise the risk. Cost associated with the implementation of control measures is only able to be considered as a final factor where the cost of the control measure is greatly disproportionate to the risk.

The WAHA would like to acknowledge the above information and guidance has been provided by the Safe Work Australia Model Code of Practice: Confined Spaces.