Article by Deborah Chick

Statistically, falls from heights remain one of the biggest causes of death, disability and injury in workplaces in Australia.

Any time there is a risk of a worker falling from one level to another, the worker is at significant risk of injury and needs to be protected. When each of us turn up to work, our employers have a legal obligation to provide us with a safe work place and we each have our own legal responsibility to ensure we take all reasonably practicable steps to make sure that everyone goes home at the end of the day.

Understanding our responsibilities is vital to ensure there is consistency across our industry and every workplace.

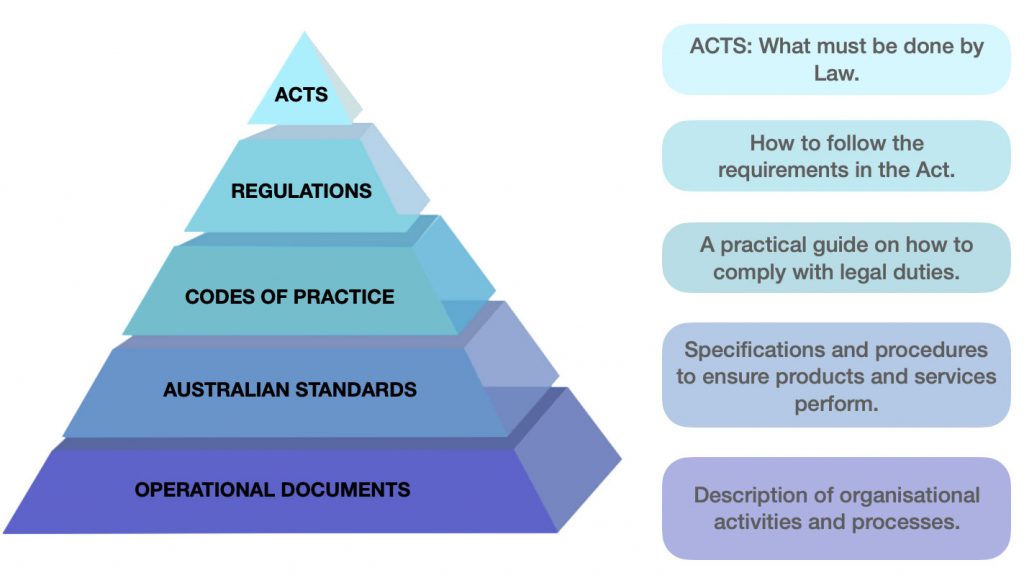

There are a number of documents available to aid in the safe undertaking of works and to maintain our legal obligations. Let’s work our way from the top down!

An Act is legislation passed by parliament: a statue or law which in turn are supported by Regulations, Codes of Practice and Australian Standards.

Acts set out the broad legal / policy principles. For example, the Workplace / Occupational Health and Safety Acts provide a framework to protect the health, safety and welfare or all workers at work and of other people who might be affected by the work.

Acts are known as primary legislation; and the term legislation itself encompasses a single law or a collection of laws.

Regulations are documents that dictate how the provisions of the Act are applied. Workplace Health and Safety (WHS) / Occupational Health and Safety (OHS) Regulations specify the way in which some duties under the WHS Act must be met and prescribes procedural or administrative requirements to support the WHS / OHS Act.

Further guidance for person(s) conducting a business or undertaking (PCBU) are Code of Practice or Compliance Codes. These establish and document a practical guide to achieving and maintaining standards of health, safety and welfare. Codes of Practice (COP’s) are developed with consultation with industry bodies, and are subject to review to ensure the content remains relevant and appropriately reflects current industry best practice and new equipment, technology and working practices are developed.

A code of practice applies to anyone who has a duty of care in the circumstances described in the code. For most cases, an approved code of practice would achieve compliance with the health and safety duties in the Workplace Health and Safety Act. Like regulations, codes of practice deal with specific issues and they do not cover all hazards or risks that may arise.

Codes of practice are admissible in court proceedings under the Workplace Health and Safety Act and Regulations. Courts may regard a code of practice as evidence of what is known about a hazard, risk or control and may rely on the code of practice when determining what is reasonably practicable in the circumstances in which the code relates.

SafeWork Australia has developed Code of Practice / Industry Codes to provide practical guidance on how to meet the standards required under the Workplace Health and Safety Act and Regulations: however, the Commonwealth, States and Territories are responsible for implementing, regulating and enforcing Workplace Health and Safety laws in their jurisdiction. Therein lies a notable distinction between State or National (Government) based Codes of Practice and industry based codes.

In specific reference to height safety related matters, the Working at Heights Association (WAHA) has developed Industry Codeswhich seek to draw details of regulations, codes of practice and manufacturer recommendations together to provide guidance on the correct, safe installation, inspection and recertification of fall protection systems. These are intended to enhance, not replace, the codes of practice and provide all stakeholders with industry-best-practice methods for height safety systems. These codes are an example of industry based codes vs State or National based codes of practice.

The model laws developed by SafeWork Australia have been implemented in all jurisdictions except Victoria and Western Australia; Western Australia is currently consulting on options to implement elements of the model laws.

In the jurisdictions where the model laws have been implemented, each state and territory is expected to make variations to ensure the laws operate effectively in their jurisdictions. In some instances, states and territories have also made more substantial variations. This is why it is important to make sure you always consider the WHS laws that apply in your state or territory.

Additional guidance material is contained within Australian Standards. Australian Standards give us a set of guidelines, specifications and procedures to the purpose of ensuring products, services and systems are safe, consistent and reliable. They are not legally enforceable, unless referenced by legislation: but keep in mind that if a PCBU chooses to operate outside of the scope of these guidelines then they must establish, justify and document their reasoning.

Within Australia, we have several industry standards that are applicable to the working at heights and confined spaces industry sector and you can view some industry specific standards here. It is worth noting that there are additional standards that while not binding within Australia / New Zealand – they do hold merit due to the international nature of the wider working at heights industry.

There are a few International Standards (ISO Standards) that have been recently adopted by Australian Standards. The ISO is an international standards body that has a number of representatives from national standards organisations and it is currently the worlds largest developer of voluntary international standards.

Other standards that you may encounter include European Standards (EN Standards). These are developed by the European Committee for Standardisation (CEN) which is a non-profit standard setting organisation, which is officially recognised by the European Union. Equipment manufactured to these standards are widely recognised as providing an appropriate standard that is maintained across the industry irrespective of geographical location.

You can also encounter American Standards (ANSI Standards) which include development of standards with ASSE International, the International Safety Equipment Association (ISEA) and the National Fire Protection Association (NFPA).

The foundation is Operational Documents. In order to keep workers safe from the risk of illness or injury companies need to have operational and site-specific procedures, forms and documentation to assist them in meeting and maintaining their legislative duties as well as their duty of care to their employees.

About the Author: Deborah is the Secretary of WAHA and CEO of Eve Consulting. She has over a decade of business management experience in the industrial rope access and working at heights sector and is a former member of the IRATA International Health and Safety Committee. She holds multiple qualifications in the field including IOSH Rope Access Manager, QMS Lead Auditor and KONG PPE Inspector.